Materials science is a natural fit for Wisconsin manufacturing

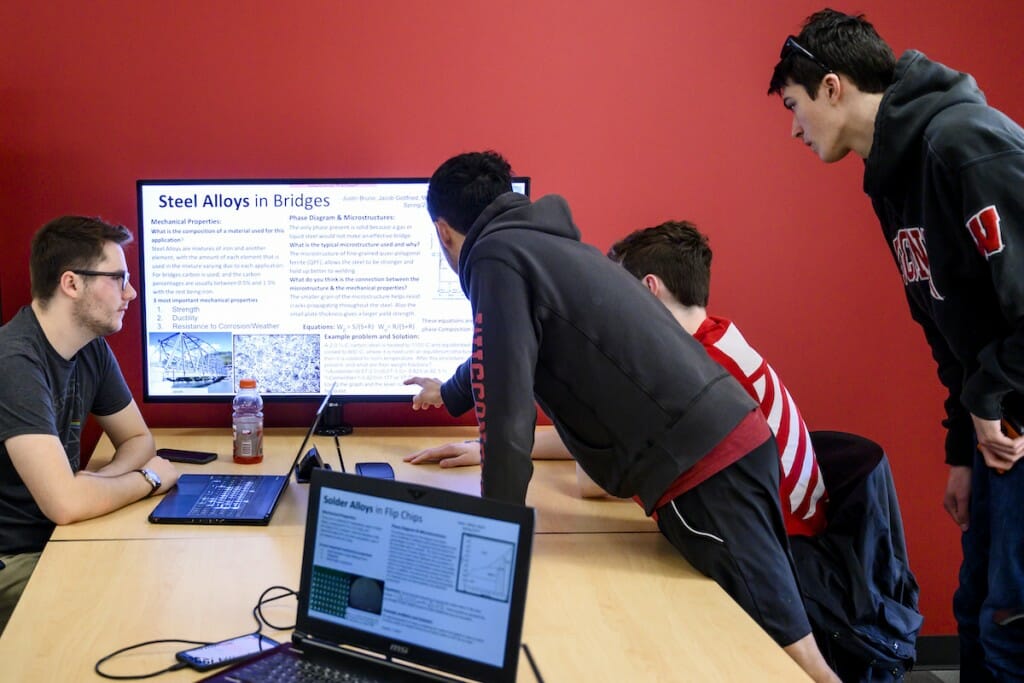

UW students take part in a Material Science & Engineering 350 class in 2019. UW materials science graduates are sought after by industry, and breakthroughs in materials developed at the university often boost local businesses. Photo: Bryce Richter

From February through June, we will highlight the ways that UW–Madison powers the state’s economy through research and innovation, educates the next generation and reaches out to Wisconsinites to improve their lives. February’s theme is Economic Prosperity. Watch for more at #CantStopABadger and #UWimpact on social media. Your support can help us continue this work.

Innovation and research are what keep Wisconsin’s manufacturing sector vibrant, and one secret weapon is the University of Wisconsin–Madison’s Department of Materials Science & Engineering.

Not only are top materials science students sought after by industry, but breakthroughs in materials developed at the university often have direct impacts on local businesses.

Materials scientists investigate a wide range of topics valuable to industry partners, from new advances in metallurgy and additive manufacturing—aka 3D printing—to new types of recyclable plastics, useful coatings and cutting-edge materials like graphene and other 2D materials.

Iconic orange-handled scissors undergoing a cycle test at Fiskars, where the quality control department is staffed almost entirely by UW–Madison materials science graduates. Photo courtesy of Fiskars

At Middleton, Wis.-based Fiskars Brands, which manufactures a wide range of gardening and landscaping tools as well as scissors with the iconic orange handles, the quality control department is staffed almost entirely by UW–Madison MSE graduates. The reason? The broad-based education materials scientists receive at UW–Madison makes them uniquely equipped to design tests, perform sophisticated quality control checks and help improve new products for the major international firm.

“UW-Madison materials science covers all the disciplines: ceramics, plastics, semiconductors, glass, metallurgy, even water chemistry,” says Fiskars senior quality engineer for product compliance Tracy Melin (MSMS&E ’91). “It is very hands-on. And when you go into industry, it’s the same thing. So, it was really good training for going out and getting a job with one of the big companies.”

In fact, UW–Madison materials scientists are sought after by companies in many industries. Each MS&E undergraduate undertakes a two-semester capstone project, which provides real-world experience and skills that tie together their academic career. Students partner with Wisconsin and national companies, including Amcor Flexibles North America, Collins Aerospace, CharterSteel, Bock Water Heaters, Thermo-Fisher Scientific and many others, and work on real research problems, the types they might encounter in an industrial research and development position.

“There are going to be a lot of us who go into industry and this is a good experience to get exposed to that and see what we’re going to do in our future careers,” says Teressa Baumann, who, along with her team, completed a capstone project for Amcor in spring 2020 before moving on to work as a research and development engineer for the Neenah, Wisconsin-based company.

The materials science and engineering impact also extends beyond educating a future engineering workforce: The research conducted by faculty and students in the department can have direct benefits for businesses based in Wisconsin. Just one of many examples is the work conducted by materials science and engineering PhD student Sachin Muley. In 2020, as part of a University of Wisconsin Advanced Materials Industrial Consortium program, Muley worked with UW–Madison alum and Madison-based NCD Technologies CEO Patrick Heaney (PhDMS&E ’09). During a 10-month project, the team set out to understand and optimize mechanical properties in amorphous carbon coatings that NCD uses for industrial applications. In particular, the company is creating new diamond and diamond-like coatings that improve the durability and precision of miniaturized tools.

Muley, for one, thinks the university and industry are great partners and that deserves more recognition. “Graduate students in science and engineering develop a lot of industry-transferrable technical and soft skills,” he says. “More should be done to help them discover opportunities in industry upon graduation.”

UW-Madison contributes $20.8 billion per year to the Wisconsin economy, and UW–Madison related start-ups contribute an additional $10 billion. Read more here.

Enjoy this story?

Read more news from the College of EngineeringSubscribe to Wisconsin Ideas

Want more stories of the Wisconsin Idea in action? Sign-up for our monthly e-newsletter highlighting how Badgers are taking their education and research beyond the boundaries of the classroom to improve lives.