Innovation institute to broaden U.S. palette of advanced materials

Graphic: The White House

Sporting sleek cases, sensitive touch screens, and an ever-increasing array of features, today’s smartphones and tablets provide consumers unparalleled mobile computing capability.

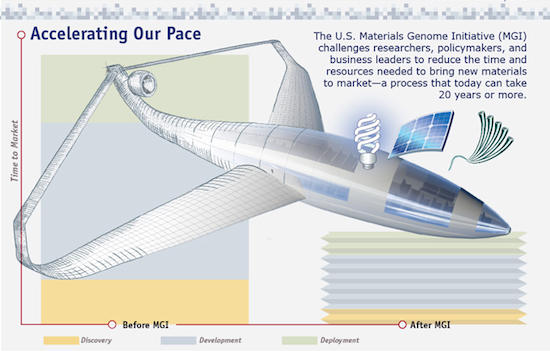

Yet, these and many other technologies are critically dependent on sophisticated new materials that can solve challenges in areas ranging from clean energy and national security to human health and well-being. And currently, a new material’s journey from discovery to commercial product typically takes as long as two decades.

With expertise in manufacturing; materials science, engineering and processing; and computer science and engineering, UW–Madison is tackling today’s materials challenges through creation of the interdisciplinary Wisconsin Materials Innovation Institute, or WIMII.

Today (June 24, 2013), the White House named UW–Madison a partner institution in its Materials Genome Initiative for Global Competitiveness, a national effort to double the speed with which the country discovers, develops and manufactures new materials.

In a 2010 photo of the scanning transmission electron microscope laboratory, Associate Professor Paul Voyles is pictured with graduate student Fengyuan Shi.

Photo: College of Engineering

“Whether we’re talking about high-efficiency, high-temperature jet engines, solar cells that generate electricity as inexpensively as coal, wind turbines that use magnets free of rare-earth elements, or the biocompatibility of replacement joints and implants, materials matter,” says Cyrus Wadia, assistant director for clean energy and materials R&D in the White House Office of Science and Technology Policy. “The Materials Genome Initiative is catalyzing important collaborative advances from industry, academia and the federal government, so that together we can secure the nation’s future as a leader in this critical technological domain.”

Building a materials innovation infrastructure is key to the initiative. The UW–Madison College of Engineering is pledging an initial investment of $5 million to create WIMII. A cross-disciplinary technological hub, WIMII will provide infrastructure for researchers in such areas as mathematics, statistics, computer sciences, information science, chemistry, medicine and engineering, and create synergy among materials researchers at UW–Madison and elsewhere.

Thomas Kuech

Researchers in the institute will interact with a variety of new and existing university, governmental and industrial partners — among them, Argonne National Laboratory and CAMECA, a world leader in scientific instrumentation and metrology solutions for the semiconductor manufacturing industry — to form the tools, teams and technologies needed to dramatically enhance U.S. materials innovation.

Additionally, UW–Madison, the University of Michigan and Georgia Tech together will begin dialog to begin building a nationwide network for materials innovation. “This will serve a national need in bringing together leaders in these various fields and to produce the means to design new materials, as well as to invent processes needed to synthesize and characterize them,” says Thomas Kuech, the Milton J. and A. Maude Shoemaker and Beckwith-Bascom professor of chemical and biological engineering at UW–Madison.

Dane Morgan

Kuech will co-direct WIMII with Dane Morgan, an associate professor of materials science and engineering at UW–Madison.

In the past, researchers created materials with new functions or forms simply by processing existing compounds or materials in different ways. However, as manufacturing and technological demands increase, researchers now need to develop capabilities that allow them to understand and design completely new materials at the atomic and molecular levels.

“Discovering new materials is an increasingly interdisciplinary process, requiring access to advanced computer simulations, large databases and a multitude of sophisticated tools for synthesis and characterization,” says Morgan. “Developing integrated multidisciplinary teams to tackle all these components is critical to accelerating our rate of materials innovation.”

In an effort to create not only innovative materials, but also methods and tools that allow researchers to study and make those materials, WIMII will leverage computational, experimental and data analysis infrastructure and expertise at UW–Madison.

In particular, UW–Madison researchers are poised to address challenges associated with the vast amounts of experimental and computational data generated by materials analysis, synthesis and characterization efforts. “This growing amount of data is being generated from a wide variety of sources worldwide and is an essential, largely untapped, resource,” says Kuech.

“Whether we’re talking about high-efficiency, high-temperature jet engines, solar cells that generate electricity as inexpensively as coal, wind turbines that use magnets free of rare-earth elements, or the biocompatibility of replacement joints and implants, materials matter.”

Cyrus Wadia

A critical part of the materials investment is to develop new means with which researchers can collect, assemble and draw on this worldwide database of materials information. “We must develop software to extract trends and understanding from this data,” says Morgan. “WIMII will help develop and integrate a powerful web of simulation tools that can seamlessly interact with these enormous databases to model materials synthesis and performance from the atomic to macro scale.”

An increasing fraction of patents for new materials comes from outside the United States and U.S. researchers are at a competitive disadvantage in developing transformative materials that are discovered outside the country. WIMII is supporting the U.S. Materials Genome Initiative to ensure the country continues to lead in materials innovation.

Ultimately, WIMII discoveries will help broaden the palette of advanced material discoveries within the United States. “UW-Madison plays a major role in innovation and spin-off companies and this institute will provide a broader base to accelerate that innovation,” says Kuech.