Fundamental discovery slashes energy cost of chemical reactions

In research that could one day allow fuel cells to be fueled by biomass rather than hydrogen gas, a University of Wisconsin–Madison lab has found a pair of catalysts that oxidize alcohols with significantly better energy efficiency.

Alcohols are a broad group of organic chemicals abundant in biomass, ranging from cellulose and sugars to lignin, the woody portion of plant stalks and trees. The study, published today (June 27, 2016) in the journal Nature, examined the “electrochemical” oxidation of alcohols. This process converts the chemical energy present in these organic molecules into electricity.

Shannon Stahl

Artavazd Badalyan

“When an organic molecule undergoes a chemical reaction, it is often more efficient for the electrons to move in pairs,” says Shannon Stahl, a professor of chemistry. “But many catalysts, especially those composed of iron, copper and other abundant elements, are only effective in shuttling one electron at a time.”

Building on earlier studies in their lab, Stahl and postdoctoral researcher Artavazd Badalyan identified a “cooperative” catalyst with two components capable of moving two electrons, using no more energy than what is needed to move one electron.

In energetic terms, Stahl says, “we get two for the price of one, and we can save half a volt relative to one of the most widely used catalysts. In a fuel cell, that is significant saving of energy.”

The study was inspired by Stahl’s previous discovery of a catalyst that uses oxygen to selectively oxidize complex compounds in drug production. Stahl began wondering why the catalyst was so selective, and found that the special selectivity was connected to the catalyst’s unique mechanism of action. “It occurred to me that what makes this catalyst so selective might also allow us to save energy in electrochemical alcohol oxidation.”

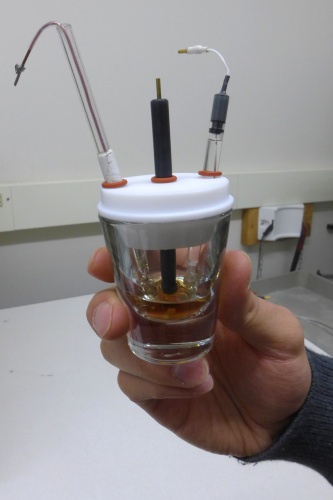

The apparatus used to demonstrate new catalysts for alcohol oxidation that reduce the amount of energy needed in the process. Photo: David Tenenbaum

A key to the advance is the simultaneous movement of an electron and a proton. “You can get more energy efficiency if the electron and proton move together because you avoid charge build-up, which costs energy,” explains Badalyan. A similar mechanism of alcohol oxidation occurs in nature in an enzyme called galactose oxidase, which oxidizes the alcohol groups on sugars.

The catalyst system presented by Badalyan and Stahl consists of two different molecules. One is called TEMPO, and the other is a molecule that contains copper. “This co-catalyst system represents a unique class of electrocatalysts for alcohol oxidation,” Badalyan says.

The research was sponsored by the Great Lakes Bioenergy Research Center. The new copper/TEMPO catalyst was discovered in the course of work focused on oxidation of alcohols in lignin, a hard-to-use byproduct of paper manufacturing. Earlier work by Stahl had shown that oxidation methods could promote lignin conversion to valuable chemicals.

“If you are going to use an electrochemical method for biomass conversion, the cost of electricity matters,” Stahl says. “The more energy efficient you can make the process, the lower your overall costs will be.”