Unique engineering shop looks to another challenge of 21st century physics

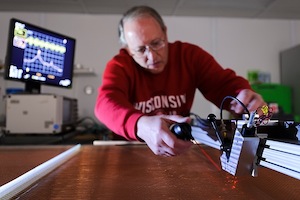

Associate instrument innovators Leland Greenler, left, and Dan Wahl measure the individual tension of thousands of tiny woven wires that make up a prototype neutrino-target screen being designed at the UW–Madison Physical Sciences Lab.

Photos: Jeff Miller

Sequestered in the farmland near Stoughton, an unusual UW–Madison facility — part machine shop, part design lab, part physics outpost — continues to make machines, equipment and detectors for the world’s most advanced experiments.

When physicists announced over the past year the discovery of the long-sought Higgs boson at the world’s largest particle accelerator, the advance depended on a 14,000-ton detector that was co-designed by engineers at the Physical Sciences Laboratory, or PSL. While the largest components were built elsewhere, some of most delicate and critical parts were made at PSL headquarters.

When scientists at the South Pole measure the world’s shyest particle — the neutrino — with a billion-ton telescope called IceCube, they are using detectors and equipment largely designed and built over a 12-year period at PSL. (The massive quantity of ice is needed to detect particles that usually pass unscathed through almost any amount of mass.)

The next big challenge for PSL also concerns neutrinos — but these will not come from mammoth explosions in outer space. Instead, they will be generated at a giant accelerator at Fermilab, near Chicago, and shot underground to a target in the Black Hills of South Dakota. The Long-Baseline Neutrino Experiment is supposed to help explain why the universe is dominated by matter and not its twin, anti-matter.

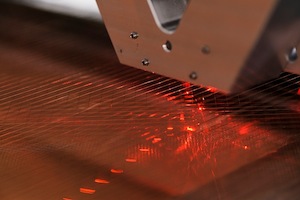

Dan Wahl uses a computer-controlled laser to measure wire tension.

The targets that PSL is designing look like a cross between an old bedspring and a window screen. Each panel — 120 of them will be needed for the experiment — has eight layers of nearly-invisible wire that must be exactly tensioned to equalize sag. The panels will operate inside a giant tank holding 10,000 tons of liquid argon, says lab director Farshid Feyzi, a mechanical engineer who has been at PSL since 1983.

The prototype is being used to explore how to automatically string the wires with precise control, and to test that the assemblies will work at liquid argon temperature (-303 degrees Fahrenheit), Feyzi says.

The Long-Baseline Neutrino Experiment is not scheduled to begin operation until 2022, but PSL always enters the picture long before the champagne gets poured. Why is Wisconsin such a frequent player in the biggest physics experiments? “Because we have a lot of expertise,” says Feyzi. “For almost 50 years we have been working with physics groups, on projects from small to large. Getting the LBNE project is nothing new. For us, nothing is too big, too small, or too unusual.”

One of the smallest projects recently is serving in an experiment on healing bones at the Department of Biomedical Engineering. “They needed something small and delicate, and titanium is incredibly strong,” says engineer and shop supervisor Rory Holland, who designed a titanium bar — less than 2 inches long and weighing less than one-tenth of an ounce. “Last week, the researcher emailed a sketch and asked for four of them. In three days, we had the parts shipped out to him.”

Engineering researchers, including those who study engines, are “tremendous customers for small projects,” Holland adds. “We usually have something for them every week.”

The prototype screen will be the basis for 120 such target panels that PSL is creating for the Long-Baseline Neutrino Experiment, set to begin operation in 2022.

Years before digital photography, PSL constructed a system to measure and digitize human motion for the UW–Madison Dance Department. And when the Wisconsin Department of Natural Resources wanted to sample pollutants running off from parking lots, PSL designed jars that could open when the rain began, and automatically take samples at set intervals.

Small projects are welcome, Feyzi says, “and we have great skills at solving problems large and small.”

But the photos on the walls reveal that the real excitement comes from experiments that could change our understanding of the nature of reality. These entail inventing strange and powerful designs. “Experiments can only do what you can make,” says mechanical engineer Leland Greenler. “Someone has to come up with a theory, and the experimental physicists have to translate that into an experiment — and then we engineers have to think about whether it’s possible to make that experiment.

“Budgets are usually characterized as frustrating, but they can be fun,” says Greenler. “If they don’t have the money to do something, are we clever enough to overcome that? Is there a way we can achieve what the physicists need with simpler equipment? A different design? Often it’s a process of taking all the constraints into account, the budget, the theory, the laws of nature, and finding a grand compromise.”

Tags: engineering, physics, research